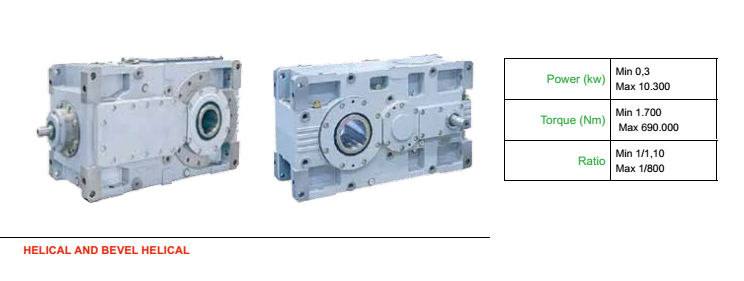

HELICALAND BEVEL HELICAL GEARBOXES

Our reduction gears main constructive characteristics are:

Casings built in cast iron and worked externally on all faces as to have a wide fixing and assembly possibility. After working, helical-toothed cylinder gears are treated with casehardening, quench hardening and tempering before grinding the involute profile. Spiral conical gears are built in alloy steel, cut with the GLEASON system, casehardened, quench hardened and torque lapped on the ideal generating rolling curve. Load and resistance capacity of the same gears has been calculated on pitting and on breakage based on the regulations:

Helical gearboxes certifications:

ISO/DIN 6336 (recommendation projects)

DIN 3990

AGMA 2001-B88

Reduction gears slow shafts, except for hollow shafts, are built in 42CRMO4 steel while fast shafts (input) are built in 16CrNi4 UNI 7846-78. Used bearings are tapered rollers or revolving rollers, of high quality and duly sized to grant a long life in required lubrication conditions. Good components execution as well as accurate assembly achieve good efficiency which assumes the following values based on the reduction stages:

0.985 at one reduction stage

0.97 at two stages

0.96 at three stages

0.95 at four stages

SPIRAL BEVEL GEARBOXES

| Spiral bevel gearboxes BG incorporate the most modern advances in bevel gearbox design and construction.

These gearboxes offer an extensive range of ratios together with an excellent power to size relationship as well as low noise levels even at high speed operation.

On request and dependent upon speed type BG spiral bevel gearboxes may be assembled with minimum backlash. Due to the quality of the gears and machining tolerances, an overall efficiency of between 94 and 97% con be expected. The modular construction of BG spiral bevel gearboxes permits up to six input/output shafts (except ratio 1:1). |

REVERSING SPIRAL BEVEL GEARBOXES

90 Degree Reversing Spiral Bevel Gearboxes

90 degree reversing spiral bevel gearboxes are available with ratio 1:1 and 1:2 only.

The 90 degree reversing spiral bevel gearboxes by moving the control lever from fully engaged through neutral to fully engaged in the apposite direction the 90 degree shaft will change rotation.

Operation of the lever, which is normally carried out by end, may only be done when the unit is stationary.

Engaging position is usually indifferent, and reversing spiral bevel gearbox is called FP (Full Position).

On request may be supplied with option SP (Single Position) and is possible only one engaging position on 360 degrees.

Reversing bevel gearboxes are produced in sizes BG32, BG42, BG55 only.

Selection corresponds to input kW and output torque as pages 5-6 reduced by 30%.

Co-axial Reversing Spiral Bevel Gearboxes

Co-axial spiral bevel gearboxes are available in ratio 1:1 only.

The co-axial reversing spiral bevel gearboxes by moving the control lever from fully engaged through neutral to fully engaged in the apposite direction the co-axial shaft will change rotation.

On request co-axial reversing spiral bevel gearboxes may be supplied with a third projection shaft at 90 degrees.

Operation of the lever, which is normally carried out by hand, may only be done when the unit is stationary.

Co-axial reversing bevel gearboxes are produced in sizes BG24, BG32, BG38, BG42, BG55 only.

Selection corresponds to input kW and output torque as pages 5-6 reduced by 30%.

Disengaging Spiral Bevel Gearboxes

Disengaging spiral bevel gearboxes are manufactured in ratio 1:1, 1:2, 1:3 only.

Operation of the lever disengages the 90 degree shaft.

This is normally carried out by hand and may only take pace when the unit is stationary.

Disengaging spiral bevel gearboxes are produced in sizes BG32, BG42, BG55 only.

Selection corresponds to input kW and output torque as pages 5-6 reduced by 15%.

PHASE-SHIFTER GEARBOXES

P.C.M.’s FR series phasers are based on the principle of the epicyclic gearboxes, with the exception that the outer crown is not integral to the body but is coupled to an endless screw.

By turning this screw, called correction, it is possible to increase or decrease the output speed while keeping the input speed unaltered, or rather to change the reciprocal positions between the input and output shafts.

For this reason, the phasers find extensive application in all those areas where it is necessary to maintain a synchrony or a movement timing between the different stages of a machining.

They are therefore used in many different applications such as:

- Typographical and printing machines.

- Plants for paper and cellulose processing.

- Packing and packaging machines.

- Sheet metal making machines.

- Industrial robot.

- Transport tapes or power lines.

- Servomechanisms in general.

They have the following constructive features:

- The boxes are made of mechanical cast iron, machined on all exterior faces and painted entirely with oil-resistant paint.

- Helical conical gears are manufactured in alloy steel, cut with the GLEASON spiroid system, cemented, hardened and lapped in pairs on the ideal generator.

- The shafts are made of hardened steel, rectified in every part.

- The worm screw assembly / helical crown is irreversible.

- The worm is made of 18NiCrMo5, hardened and rectified.

The helix crown, internally and externally, is made of 41CrAlMo7 and treated with SULFINUZ to improve performance in terms of fatigue strength and surface hardness, and also obtain a low coefficient of friction between the parts in contact and a high effect anti-seizure.

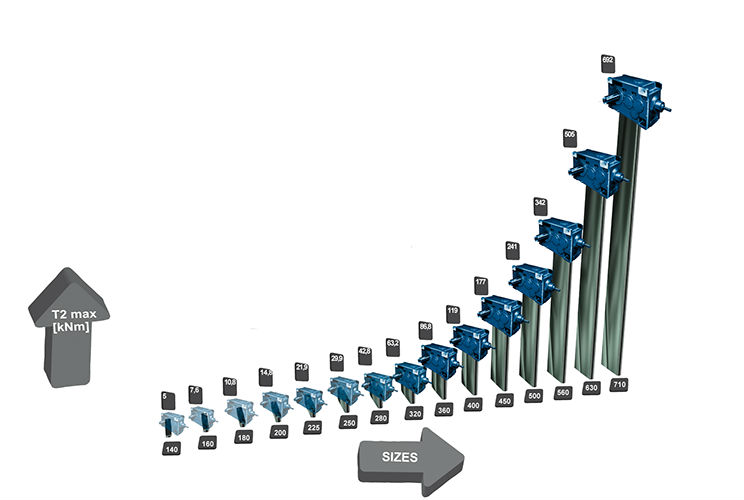

SCREW JACK

Mechanical screw jacks series S, could be used in the following fields: lifting, travelling, handling and any type of linear traverse requiring high thrust capacity.

Screw jack with travelling spindle. Rotation of the worm wheel generates axial movement of the threaded spindle as it is thrusted by the ring gear of the screw jack.

Thanks to their manufacturing simpleness, make them highly resistant and suitable to be used also under heavy conditions, besides lubrication by means long-lasting lubricant reduce the maintenance.

Should they are installed in a same plant, they could be series connected by shafts, couplings and spiral-bevel gears in order to synchronize them perfectly; in this way out of balance loads could also be controlled,

All screw jacks could be also used for:

- alternating or direct current motors;

- hydraulically-operated motors

- pneumatic motors

- manually-operated control

The following manufacturing materials are used, aside from the dimensions:

- housing, covers: G22 grey cast iron

- worm: 39 NiCrMo5Pb

- ring gear: GCuSn12 bronze

- threaded spindle TPN: steel R80 (36 SMnPb14 obtained by chip forming machining)

Listed here all our gearboxes, universal shafts, gears and couplings.